About SimCast Dental Labs

Here at Simcast Dental Laboratories, we pride ourselves on our high-quality, digitally-produced and hand finished frameworks that we guarantee will fit your client.

As well as this, we offer fast turnarounds of just 5-6 working days after we receive your case.

With over 40 years of experience of manufacturing chrome partials, you can trust our technicians to provide you with a high end but affordable service.

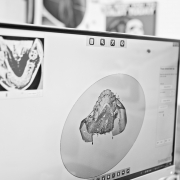

𝐃𝐢𝐠𝐢𝐭𝐚𝐥𝐥𝐲 𝐩𝐫𝐨𝐝𝐮𝐜𝐞𝐝 𝐚𝐧𝐝 𝐡𝐚𝐧𝐝-𝐟𝐢𝐧𝐢𝐬𝐡𝐞𝐝 𝐟𝐫𝐚𝐦𝐞𝐰𝐨𝐫𝐤𝐬

We offer a digitally produced & hand finished framework on your model as sent traditionally through the post.

Alternatively you can scan your model and upload the STL file via our website. We will then produce a digital partial framework and return the finished metalwork on a highly accurate printed model. This means the working model never leaves your lab, and you receive a precise model on which you can present the finished denture to the end user.

Call us today if you would like more information about our products/services: 01202 421 442